| |

|

| |

Production Roll-Fed Ink Jet Press

| |

Since DRUPA 2008 ink jet technology started to replace toner based in production digital printing. Still this process is very slow thanks to the fact there is huge gap in pricing newer to older technology machines (2.5+ times). Our goal is to fill that gap introducing affordable, scalable, best quality of design, components, serviceability, flexibility and reliability solution with way better total cost of ownership for best user investment protection. Solution is designed to integrate different technologies widening the range of applications by far to extend business opportunities for our customers. Market approach would be through OEM agreements and we expect achieving big number of sales, mainly to small and medium sized companies protecting long years established businesses both of users itself and their suppliers of printing machines from collapsing under pressure of IT technologies. We are talking hundreds of sites only in Europe and 20+ million annual turnover of every OEM partner.

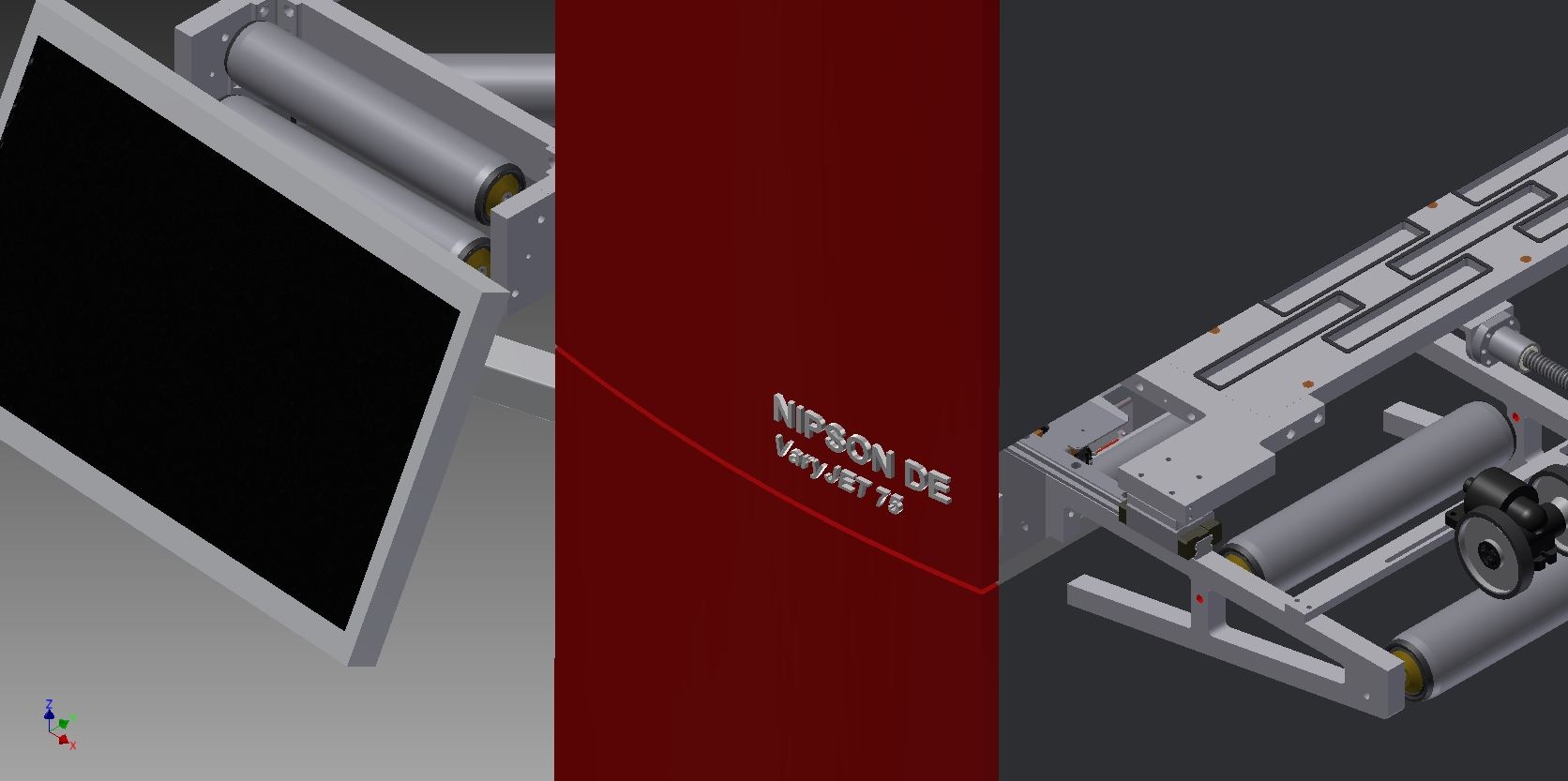

Development started on order for ink-jet module to established brand in digital printing presses with very strict requirements to size, flexibility, serviceability and quality. At some stage it was decided instead of making specific module to create independent printing system, but previous development already generated most of advantages. Main one is very simple design compared to market leaders – Kodak, Canon and HP with matching quality of print. Comparable HP T260 has size of 3.0x12.2x2.7m and consumes 43kW while our prototype is 1.3x0.8x2.1m and consumes less then 2kW. Canon/OCE Jetstream 1000 which is using same ink jet heads as our prototype and is with the same printing specs is sized at 6.1x2.7x2.25m and uses 29kW when printing. Level of technology involved in our solution is matching even still in development nanotechnology of famous Mr. Benny Landa from Israel. Furthermore using same print heads as him we are involving better driving boards and ink station developed in Cambridge area, not talking German paper motion and RIP systems which are most advanced today.

Therefore we are combining very simple, serviceable, compact and cost effective design with state-of the-art technologies of near future. Cost of the machine is at least 2.5 times of any competitor, cost per print is 5 times better then of toner-based machine, service work is 2+ times less than of competition, ecology parameters are times better, footprint is w/o match. |

|

| |

|

|

| |

Technical Data (per engine)

| Throughput | up to 230 mpm (750 fpm), up to 2350 A4 ppm, 8, 12, 16 page signatures |

| Image quality | up to 1200x1200 dpi |

| Substrates | uncoated and coated no priming required |

| Paper thickness | 45 - 350 gsm |

| Roll width | 105 - 680 mm (4 - 26.5”) |

| Print Technology | piezo DoD up to 2 colors |

| Ink type | aqueous pigment, dye or hybrid ink |

| Imaging width | 108, 216, 325, 430, 540, 650 mm |

| Image length | no limits |

| Duty cycle | 60 million A4 or letter images/month |

| File formats | PDF, EPS, PS, JPEG, GIF, BMP, TIFF, PSD |

| Networking | Ethernet, TCP/IP, 1Gbps, twisted pair, WIFI |

| JDF/JMF | Job ticket control |

| Power requirements | 210V-240V 50/60 Hz |

| Power consumption | less then 2 KW |

| Dimensions | 1.3x0.8x2.1 m (51"x32"x83") |

| Weight | 650 kg (1450 lb) |

|

| |

|

|

|

|

|